Qinu GmbH

Morgenstrasse 8

76137 Karlsruhe

Germany

- info@qinu.de

- +49 721 957917-00

Small volume – Economic – Turnkey-ready

Cryocooler Unit

Freely Positionable

Gas-Handling-System

He-4 Pipeline

Thermally Isolated

Qinu Cryostat

on Default Table

Vacuum & Supply Lines

Still Pumping Line

Wall / Soundproof Box

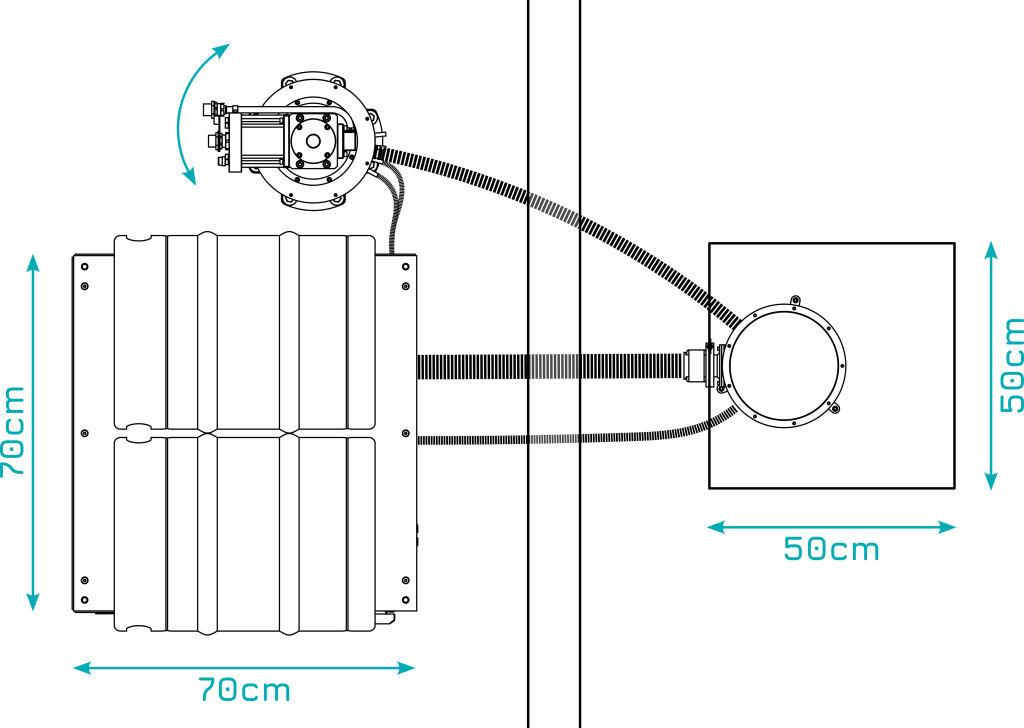

The Qinu cryostat, the Gas-Handling System (GHS) and the Cryocooler Unit (CCU) can be positioned independently of each other. This provides maximum flexibility in layout design and enables the installation of the complete system in every lab environment.

Due to the flexible connections between the three subparts and in combination with the possibility to fix the corrugated tubes to a massive wall or floor, vibrations present at the experimental stage are highly reduced. In addition, all noise emitting sources can be placed in a separate room or soundproof box.

Qinu’s cryostats come by default with a GM-type cryocooler, providing cooling power down to 4K. The CCU is connected to the cryostat via a customized and highly elaborated Helium-4 pipeline, forming a closed circuit. The CCU can operate independently from the cryostat, meaning it can cool down or remain cold while the cryostat is warm and open for sample exchange.

In addition, the CCU is equipped with an integrated cold trap, both for the Helium-3 and Helium-4 circuit, making the laborious handling of liquid nitrogen traps unnecessary.

All Qinu systems are equipped with an industrial PC, which makes them a stand-alone and independent control unit. Integration into the laboratory environment can be easily done via Ethernet connection. The integrated software is totally web-based and does not require any installation of drivers or other modules. It can operate independently, even in the event of a reception loss.

The software makes for easy system control and operation. With just one click the system cools down and warms up automatically. More elaborate operation stats such as vacuum pumping, venting, trap cleaning are also integrated.

The history feature enables the viewing and export of previous cooling processes. All parameters can be easily read out via an interface to programming environments such as Python and others. This allows a straightforward synchronization with any measurement.

Morgenstrasse 8

76137 Karlsruhe

Germany